At Mahendra Non-Ferrous, we take pride in operating a fully equipped in-house foundry that supports the complete casting process — from initial design to final inspection. Our facility enables us to maintain strict quality standards, optimize production timelines, and reduce external dependency, resulting in cost-effective and high-precision castings for diverse industries.

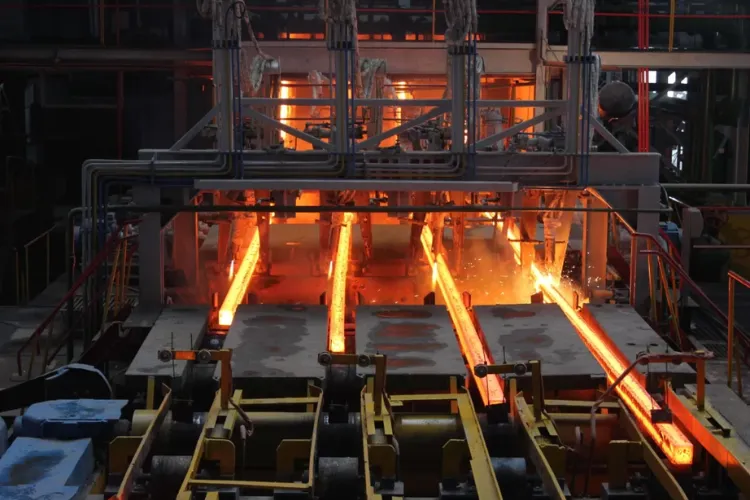

Aluminium Casting Furnaces

Our in-house furnace setup efficiently handles gun metal castings, allowing for precise control over batch sizes and alloy consistency.

Gun Metal Furnace Capacity

Melting Capacity Range: 100 kg – 150 kg per cycle

Our in-house furnace setup efficiently handles gun metal castings, allowing for precise control over batch sizes and alloy consistency.

Brass Furnace Capacity

Melting Capacity Range: 100 kg – 150 kg per cycle

Our brass melting facility supports medium-scale casting with reliable temperature control for optimal flow and finish quality.

Aluminium Bronze (Type 1 & 2) Furnace Capacity

Melting Capacity Range: 100 kg – 150 kg per cycle

Ideal for wear-resistant and corrosion-resistant components, our aluminium bronze melting setup delivers consistent metallurgical properties across every batch.

Phosphor Bronze (Type 1 & 2) Furnace Capacity

Melting Capacity Range: 100 kg – 150 kg per cycle

Our in-house setup for phosphor bronze ensures high strength, fatigue resistance, and precise alloy composition for critical industrial applications.

Uses disposable sand molds for each casting

Metal is poured manually using gravity

Low tooling cost, ideal for prototypes and custom parts

Suitable for low to medium production volumes

Slower production speed due to mold preparation

Can produce large and heavy parts

Offers flexibility in part size and shape

Surface finish is rough and usually needs machining

Dimensional accuracy is moderate

Heat treatment is generally feasible

Supports use of cores for internal cavities

Uses permanent metal molds, filled by gravity

Suitable for medium production volumes

Offers better surface finish and accuracy than sand casting

Moderate tooling cost

Slower than pressure die casting but faster than sand casting

Can produce thicker wall sections

Suitable for robust and strong parts

Sand cores can be used for internal features

Ideal for parts needing better mechanical strength

More consistent part quality over multiple runs

Uses high-pressure injection to fill metal molds

Best for high-volume production and complex parts

High initial tooling cost, but low per-part cost at scale

Very fast production cycle and excellent surface finish

Suitable for thin-walled, lightweight components

Not ideal for heat-treated parts (due to porosity)

Not suitable for large or heavy castings

Limited use of cores or internal voids

Requires precise mold engineering and control

Ideal for industries like automotive, electronics, and appliances